How to Wax Skis at Home

Waxing your skis is kind of like riding powder – it’s impossible to do it too much. Waxing on a regular basis not only makes you go faster, but it also makes turning and handling smoother and more predictable and protects your bases from abrasion. With a little practice, you can master the art of how to wax your skis and consistently outrun your partners on the flats or that high traverse to get to the goods.

First things first, there are different types of wax for different activities. For example, a downhill racer will use a different kind of wax then a cross country skier. The primary type of downhill ski wax comes in hard blocks that are melted onto the ski with an iron. There are a few other types of waxes, too, like pastes and liquids. These are made more for last-minute on-hill touchups - there’s no substitute for a good hot wax. In this guide, we’ll focus on traditional hot waxing.

Workspace & Equipment Needed

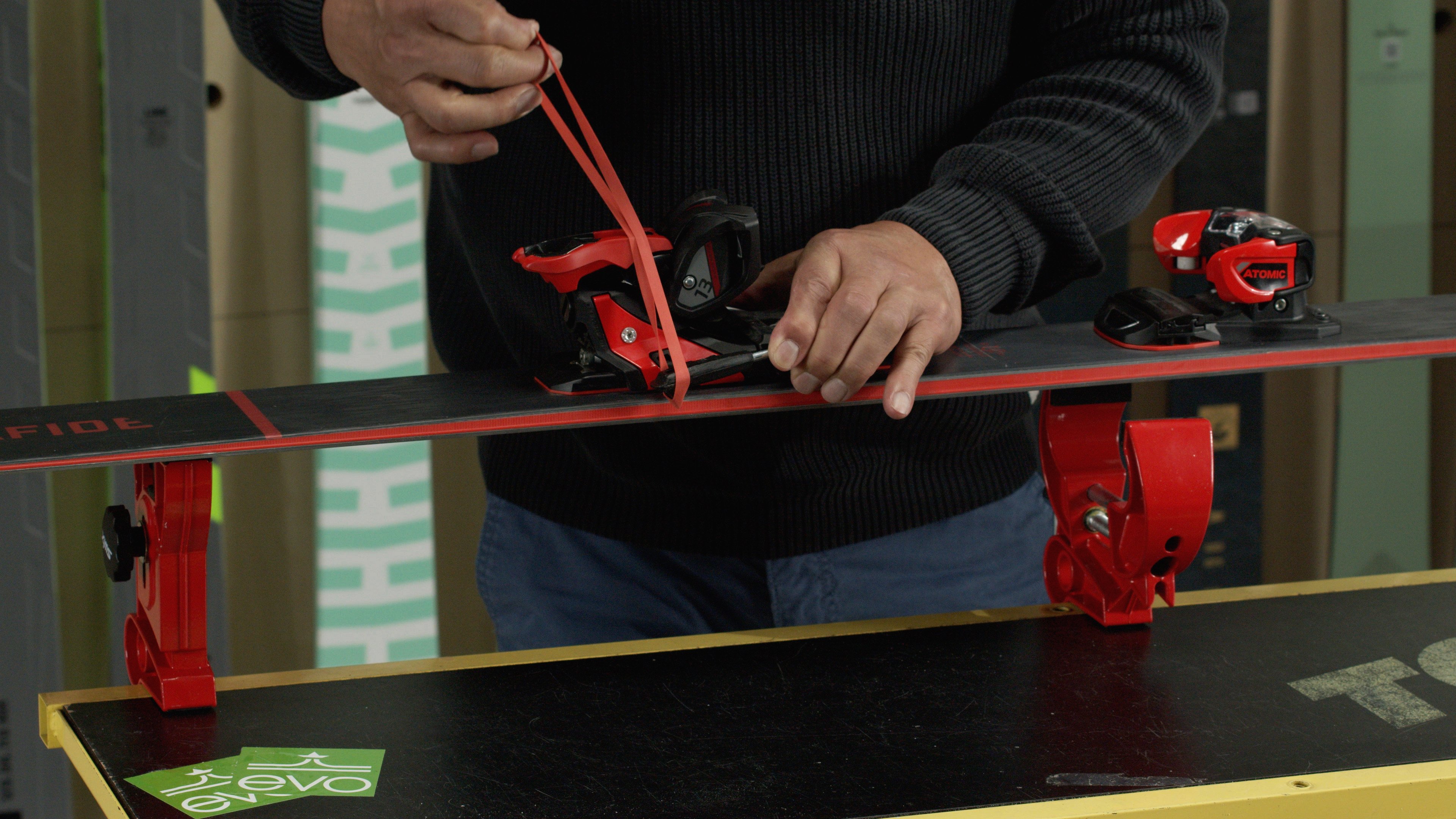

If your skis have brakes, retract them before you start working on your skis by pulling them up manually and running a strong rubber band around the brake arms and over the heel piece. This will hold the brakes in the “ski” position so they don’t extend below the base. Waxing is easiest with a ski tuning vise that keeps the skis or board level, locks them into place, and supports the tips and tails, but it can also be done with blocks of wood to elevate and support the tips and tails. It’s very difficult not to drip some wax off the skis, so if the surface below you needs protection, cover it before you start.

Ski Waxing Equipment List:

- Workbench, vices, or waxing platform

- Rubber bands to hold ski brakes up

- Wax

- Waxing iron

- Plastic Wax Scraper

- Waxing Brushes

Preparing Your Skis for Waxing

Starting with a clean and properly structured base will help you get the most out of each waxing session. Make sure the base is flat and the edges are not railed (higher than the base). You can use something like a ruler or a dedicated truing bar to check this. If your bases are not flat, you need a stone grind to correct them. If your edges or bases need a grind or other maintenance, do that before you start to wax, and make sure no metal filings are stuck in the base. If you have burrs or knicks in your edges they can scrape the base of your iron, which can in turn scratch your bases.

If your bases are dirty, you can use base cleaner or a solvent to remove grime and oil, but use it sparingly and be sure to allow the bases to dry completely before waxing. If you use a solvent, just a small splash on a cloth is plenty. Be careful, base cleaners and solvents tend to remove all residual wax left in your base, which can leave them dry. So, skip this step if your bases seem clean.

What Type of Ski Wax Should I use?

There is a huge range of waxes available, made for all different types of snow conditions. At a basic level, ski wax is either “all-temperature” or temperature specific.All-Temperature Ski Wax

All-temp or "universal" wax is designed to work well in any temperature or snow conditions. It's a good choice if the temperature varies a lot where you ride, if you don’t wax your skis that often, or if you ski in different geographical areas during your season and can’t predict what the weather will be like.Temperature Specific Ski Wax

Snow is all the same temperature, right? Not so fast, snow temperatures can vary with moisture levels, air temperature, and other factors. Temperature-specific waxes are designed to work best within a certain range of snow temperatures, providing increased performance.

Swix “8 Series” (pink) waxes, for instance, are meant for snow temperatures between 1˚C and -4˚C (34˚F to 25˚F). There is some overlap in the temperature ranges; the next colder wax, the “7 Series” (violet), is for temperatures from -2˚C to -8˚C (28˚F to 18˚F). Temperature specific waxes will still work better than no wax in temperatures outside of their “ideal” range, and it’s possible to combine two temperature specific waxes if you anticipate borderline temperatures. Using temperature specific waxes requires that you follow the weather and anticipate the temperatures you’ll be riding in, and you might find yourself re-waxing if conditions change drastically. If you’re on the fence about which temperature-specific wax to use, opt for the colder range. Colder temp waxes do better in warmer snow than the opposite.

Fluorocarbon Ski Wax

Prior to 2019, many high-end waxes designed for racing included Perfluorocarbons (PFCs) to increase speed. These chemical additives have been shown to have negative health effects and remain in the body long term. They also break down very slowly in the environment. As a result, the FIS (International Ski Federation) and most world governments have banned the use of PFCs in ski wax and fluorinated ski wax is no longer being produced.

With the FIS banning fluorinated waxes in 2021, all commercial waxes are now Hydrocarbon or Plant-Based. There are still more expensive varieties of wax available for racing, but they are considerably more expensive and none contain PFCs.

Green & Environmentally Friendly Ski Waxes

Some ingredients found in traditional ski and snowboard waxes, like fluorocarbons, have been found to have negative environmental impacts. In response, some companies have created more environmentally friendly products. They claim that these work just as well as their traditional counterparts.

What Kind of Iron Should I Use to Wax my Skis?

Sure, you can use any iron to melt wax onto a ski, it’s a pretty simple process after all, but that doesn’t mean you want to reach straight into your closet for your clothes iron. A dedicated wax iron is a good investment if you plan on waxing your own skis at home regularly; they are calibrated in degrees rather than fabric types and hold a specific wax temperature more accurately.

Can You Use a Clothes Iron to Wax Skis?

Yes, you can use a traditional clothes iron to wax skis, but there are some things to be aware of. First, don’t plan on using the iron on your clothes again - you’ll almost certainly ruin them with wax. Also, look for a clothes iron without steam holes (wax can get trapped in these), and a thick baseplate - this means more consistent temperatures.

Regular household irons fluctuate in temperature more widely than wax-specific irons and can easily be set at too hot of a temperature, causing you to damage your bases. Be careful not to overheat the wax - find a temperature that melts the wax easily but doesn't smoke when the wax contacts the iron. This is usually somewhere around the lower end of the "wool" setting or the high end of the "synthetics" setting. Anything in the cotton or linen zone will be too hot. Using a wax-specific iron, which has a lower maximum temperature, will make it easier to avoid damaging your base.

How to Wax Skis

- Secure the skis to your bench. Place your skis flat and base side up and securely supported at the tips and tails They should be clamped or braced so they won’t move while you work on them. Pull up the ski brakes and use a thick rubber band stretched between the brake arms and over the heel piece to keep them out of the way.

- Begin dripping wax onto the skis. Hold the hot iron upright with the point or one corner facing down. Press the wax to the iron, moving it around on the hot surface. This will start melting the wax, dripping a small stream onto the ski's base. You don’t need full coverage here, you’ll spread the wax over the entire base in the next step.

- Use the iron to spread the wax over the entire ski. Put the iron on the ski base and move it down the ski to melt the wax you’ve deposited on the base. The goal here is to spread the wax out evenly so it penetrates the entire base. Keep the iron moving at all times; usually, a speed of about 2 - 3 inches per second will prevent damage to the base by overheating. If the base becomes too hot to touch with your hand, you're moving too slowly!

- Let the wax cool completely. It’s best to leave your skis at room temperature until the bases feel completely cool to the touch, usually about 30 minutes. If in doubt, wait a little longer.

- Once cool, you can move on to scraping and brushing the skis.

Scraping Ski Bases

A common misconception is that wax needs to be thick to be effective. Actually, the opposite is the case; the best wax job is visible only as an oily sheen on the P-Tex, and little or no wax should come off if you scrape the base with a fingernail. As many professional tuners say, the wax should be “in the base” not “on it.”

To get the wax layer that thin, you need to scrape off the excess. Ski wax scrapers are made from polycarbonate (plastic) or steel. You should almost always use a plastic scraper, steel can remove base material and damage your bases. A sharp scraper is your best friend. You can buy a dedicated scraper sharpener, or run the flat edge over sandpaper, using a guide to make sure it stays straight.

Angle the scraper in the direction of travel and push from tip to tail to remove the wax. With any work on ski bases, you should always work from tip to tail. Under-scraping is probably one of the most common errors that beginner tuners make - you should scrape until no more wax is coming off of the base. Remember to scrape your edges as well with the end of the scraper.

Brushing Ski Bases

After you’ve scraped thoroughly, the next step is brushing. This is a step that many skiers skip, however, it does pay off in speed and performance on the mountain. There are many types of wax brushes that vary by the stiffness of the bristles. A typical quiver of wax brushes usually includes a brass brush (for base structuring and prep), a stiff nylon brush, a softer nylon brush with shorter, finer bristles, and a very fine horsehair brush. When brushing, start stiffer and progress to finer, softer brushes as you work. The idea is to leave only the thinnest layer of wax on the surface of the base and allow the structure (the fine texture of grooves and divots) of the base to show through.

Brush from tip to tail in short to medium strokes, about 6” at a time, and keep at it until the base is uniformly oily and glossy looking. As you work you’ll notice tiny white flecks of wax being deposited at the end of each stroke, even when it appears all the surface wax is gone – that’s the wax being pulled out of the structure to make you fast-fast-fast. You’ll notice less and less wax coming out of the base as you brush more. It’s pretty hard to over-brush but keep at it for five to ten minutes or so or until you get tired. Finish off with several full-length tip-to-tail strokes, and you’re ready to ride.

How Often Should You Wax Your Skis?

Now that you know how to wax your skis, you're probably wondering how often you need to re-apply wax. You really can't wax too often, but the frequency that your skis demand a fresh coat of wax depends on several factors.If you see "hairs" or white patches in the base material, or if you simply aren't keeping up with others around you, you are overdue for a wax. Sintered bases (used on most high quality skis and snowboards) will show dryness more quickly, as the base material is more porous. Dry spots won't be as obvious with Extruded bases (normally found in price point skis and snowboards or those intended for park use), as the base material is solid, but regular waxing will still improve performance.

Temperature variations are another consideration. Because different waxes are made for different snow temperatures, it's best to wax if there is a large temperature fluctuation and your wax is no longer appropriate.

Ultimately, there's no set amount of time or a definitive number of ride intervals when it comes to waxing. Some skiers re-wax their skis every time they go out, while others only wax once or twice per season...

For most skiers, however, it's optimal to wax your skis again after 3-5 days of riding. If you're in doubt, take a look at your bases; if they look "dry" like the photo below, you'll benefit from a fresh wax.

This is evo. We are a ski, snowboard, wake, skate, bike, surf, camp, and clothing online retailer with physical stores in Seattle, Portland, Denver, Salt Lake City, Whistler, and Snoqualmie Pass. Our goal is to provide you with great information to make both your purchase and upkeep easy.

evo also likes to travel to remote places across the globe in search of world-class powder turns, epic waves, or legendary mountain biking locations through evoTrip Adventure Travel Trips. Or, if you prefer to travel on your own, check out our ski & snowboard resort travel guides and mountain bike trail guides.

Still have questions? Please call our customer care team at 1.866.386.1590 during Customer Care Hours. They can help you find the right setup to fit your needs.